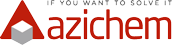

THE PROBLEM

The waterproofing of underground structures represents a significant problem in the field of foundation engineering.

The water can cause the early deterioration of the works both for physical effect, due to the penetration in the support, and for the chemical degradation; water in fact normally appears as a saline solution of chemical agents that can interact and affect the cement matrix of the works.

In any case, the final result is the unforeseen deterioration and damage of the structures, both in terms of static resistance and of functionality of the work. It is therefore a fundamental requirement for underground structures to have a correct waterproofing that ensures, during the entire life of the work, complete compliance with the operating variables.

THE SOLUTION

A first analysis of the possible solution for the waterproofing of underground structures leads to the distinction between “passive systems”, which are limited exclusively to fulfilling the function of barrier, hindering structure/fluid contact and “active systems” capable of interacting with the fluid itself, inhibiting possible infiltration ways even in an advanced state of operation of the work. Bentonite geosynthetic barriers belong to this second category.

A bentonite geocomposite can be defined as a hydraulic barrier consisting of a low permeability bentonite layer, supported by geotextiles or geo-membranes, assembled with different principles.

You can think about the “bentonite geocomposite” as a bentonite container; bentonite is the waterproofing matrix and containment geotextiles the protective element that gives mechanical resistance to the barrier system.

CLAYTEX: Waterproofing geotextiles based on sodium bentonite.

The CLAYTEX sheets consists of two permeable geotextiles assembled in such a way as to host, inside them, granular sodium bentonite with a high content of montmorillonite (greater than 95%).

GENERAL CHARACTERISTICS

Water-activated natural sealant, self-sealing; porous protective sheets to allow quick hydration; continuous and uniform flexible bentonite layer, resistant to biological and environmental attacks; does not age over time.

APPLICATIONS

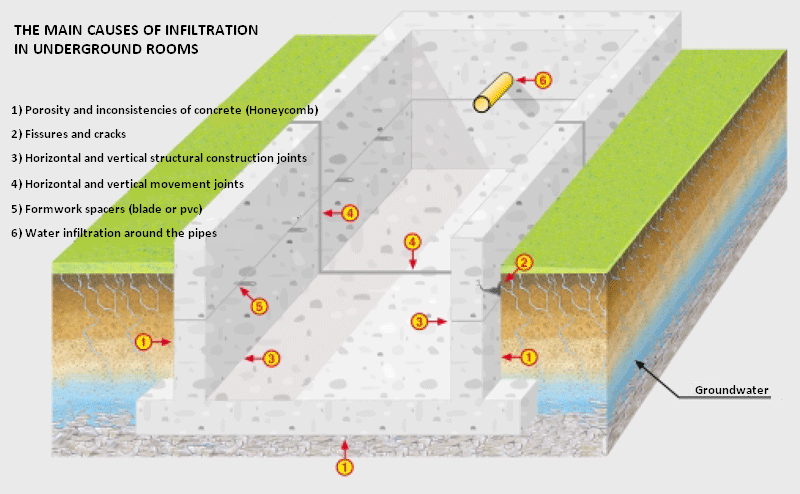

This system allows waterproofing with a high level of underground construction safety. After the sheets have been applied to the structures, the filling material (sand) is backfilled and compacted to confine CLAYTEX against the support. When the geotextile adheres to the structure and is confined by filling materials, the pressure of the latter prevents the bentonite from fully expanding, causing the formation of a sticky gel, consistent, impermeable to water and self-sealing. In the presence of cracks or deformations of the structure protected by CLAYTEX, the residual expansion potential of bentonite means that the latter can expand further, even after years of laying, sealing cracks up to 3 mm.

SUPPORT PREPARATION

The surfaces of the walls must be free of bumps and cavities. The holes of the formwork spacers, the rebend connections and gravel nests must be sealed with non-shrinking mortar from the REPAR Line of Azichem srl, or osmotic cements of the OSMOCEM Line of Azichem srl or with composites based on sodium bentonite CLAYGRAIN.

GEOTEXTILES INSTALLATION ON HORIZONTAL SURFACES

In the event that CLAYTEX is applied directly on the ground or below structural slabs, the substrate must be well compact and composed of a fine and homogeneous natural material. Otherwise it will be useful, when not essential, a layer of concrete 7-8 cm thick.

The darker face, should be left facing upwards.

As the CLAYTEX sheets is laid and nailed onto the concrete substrate, it must be covered with a further layer of concrete 5 – 6 cm to avoid possible damage caused by sudden rain or by laying the reinforcement of the next slab.

GEOTEXTILES INSTALLATION ON VERTICAL SURFACES

The bentonite sheets must be applied on the vertical surfaces starting from the bottom.

Each CLAYTEX “small” geotextiles has a size of 1.20 x 5.00 meters and is therefore easily applicable using 5 – 6 cm masonry steel nails and plastic washers or similar materials suitable for the purpose. The darker face, should be left facing outwards.

The lower row of carpets must be turned up around the base of the foundation and adhere as much as possible to the internal corners, where possible, beforehand rounded, by means of curve cementitious shapes, two-component, osmotic mortar OSMOCEM RD from Azichem srl.

All adjacent sheets must overlap by at least 5 cm. The rows of carpets subsequent to the first must be applied taking care to offset the vertical joints. CLAYTEX requires no additional protection. If the situation allows it, the filling material (sand) must be appropriately placed against the carpets, in successive layers with a maximum height of cm. 60 – 80, correctly compacted and possibly moistened. If backfilling is not possible immediately, the dark plastic film can provide temporary protection against atmospheric precipitation.

The CLAYTEX system, easy to apply, requires minimal preparation of the surfaces. No background primer is required; it can be laid on fresh concrete, even if dirty or dusty; no sheets, fabrics or other protective materials are required; the incidence of laying is compatible with most drainage systems; there are no restrictions regarding the application temperature.

LIMITATIONS AND PRECAUTIONS

CLAYTEX geotextiles cannot be installed on roofs, tunnels or structural platforms, in the absence of adequate protection covering, represented by at least 20 cm of concrete or 50 cm of soil.

The bentonite sheets must be protected from rain and water of any origin, for example with polyethylene sheets, until the backfill or contrast material is laid. In the event of damage, resulting from abundant atmospheric precipitations occurring before the adoption of the protection means, the damaged and/or swollen parts must be replaced, to recreate the correct continuity of the waterproofing.

In the presence of soils with high salt contents, as well as of acids or alkalis, appropriate soil samples must be taken, to be sent to the AZICHEM laboratory for analysis and possible preparation of specific installation instructions for the CLAYTEX geotextiles.

For the installation on masonry of bricks or cement blocks it is necessary to provide for the preliminary plastering of the contact surfaces, with sand and cement mortars.